Product

ProductEMP Protection

EMP Protection System

ERETEC has successfully carried out EMP business based on the know-how accumulated from EMC system supply and installation.

As a construction infrastructure, EMP protection project requires E.P.C (Engineering and Procurement Construction) and ERETEC provides a variety of solutions to meet customers’ demands using design capabilities and project management skills.

EMP Protection System

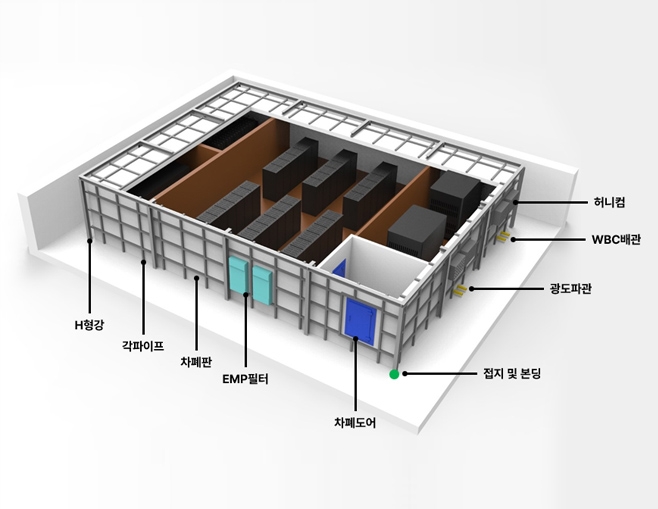

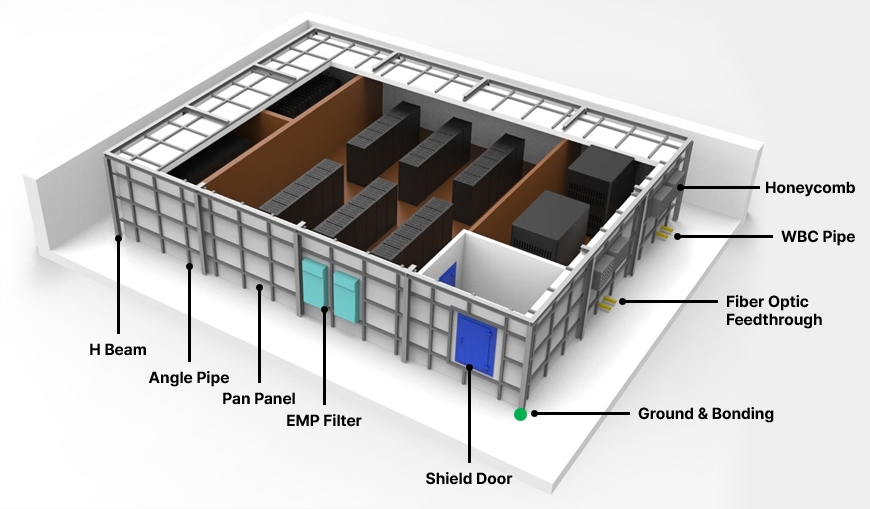

Configuration

| EMP Protection Facility | Main POEs | Performance Test | |

|---|---|---|---|

| Architectural PoE | H Beam/ Angle Pipe | • Design and install of self support steel structure and angle pipes for fixing pan panels. |

• SE Test • SELDS Test • PCI Test |

| Pan Panel | • Welded structural steel sheet & galvanized steel sheet/ Installation method : WELDING & PAN TYPE | ||

| Shield Door | • Entryway shielded door / Design and installation with interlock system | ||

| Electrical PoE | EMP Filter | • Conductive EMP threat protection with power/control/signal line filters | |

| Fiber Optic Feedthrough | • Standard audio and data lines to convert to fiber optics. (Fiberoptic converter & fiber optic cables) | ||

| Ground & Bonding | • Prevent potential difference within EMP protection facility / Electrical bonding of equipotential ground plane by exothermic welding | ||

| Mechanical PoE | Ventilation PoE | • Honeycomb design and installation for ventilation and generator flue systems | |

| Piping PoE | • Sigle WBC or WBC arrays’ design or installation for mechanical pipes (Oil, Water, Fire extinguishing gas) | ||

| Standard | • MIL-STD-188-125-1 | ||